MACHINERY & PRODUCT QUALITY_

With its professional equipment and an experienced team of specialists, our production department ensures the highest quality of the manufactured products.

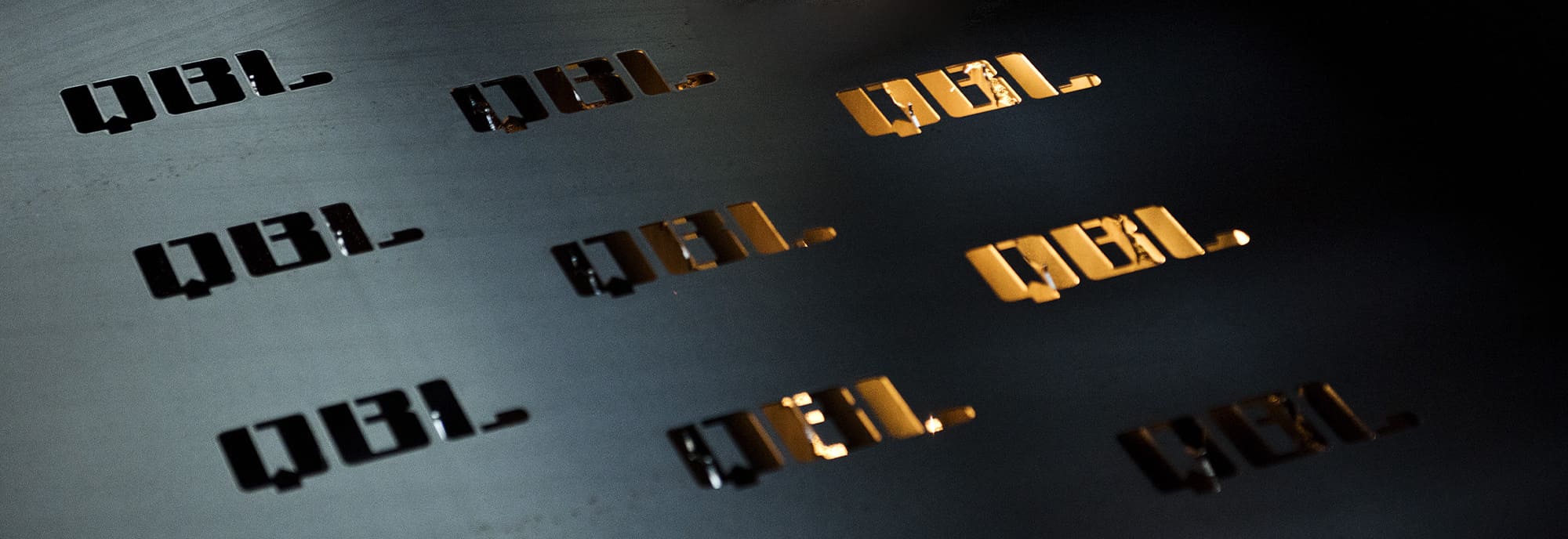

We achieve it thanks to technologically advanced, digitally controlled devices that guarantee consistent results and minimise the human risk factor in tasks that require uncompromising precision. High quality raw materials and semi-finished components we use are of key importance in the production of QBL products.

Most components of racks (levels, angle bars, hoods, shelves, rails, or hooks) are produced from galvanised or stainless steel. The various shapes of steel elements are lasercut into three-dimensional forms, some of which are then stamped, welded and ground. Painting – which takes place in our modern powder paint shop – in addition to the wide application of galvanised sheet metal - permanently protects the surface of those elements which are most exposed to scratches and, consequently, prone to corrosion.

SEE ALSO_