PERSONALISATION

SELECT FROM VARIOUS MATERIALS & COLOURS

Most of the furniture and products of the UniQ and Sequence lines – both racks, dryers and depot lockers – have been designed to create customised, consistent and truly unique spaces. The interchangeability of external elements means individual matching of the appearance of products to the aesthetics of the interior and character of the environment in which they are located. Thanks to a well-thought-out design, it is possible to match it with a wide selection of materials, models and colours – MDF, veneered boards, natural wood or steel surfaces. The variety of options contributes to the flexibility of designing spaces and creating cohesive compositions – all reflecting the nature of the place and the community.

DOUBLE PROTECTION

DURABILITY & PROTECTION AGAINST CORROSION

The key elements of racks and dryers exposed to corrosion (such as frames, levels, angles or shelves, as well as depot lockers structures) are made of high-quality galvanised steel. During the final stage of production, all elements are subject to automated powder coating. Galvanised steel and a thick layer of coating provide double protection for the products against moisture. In addition, the rack structures have been designed to prevent water accumulation inside the

FOUR VISUAL LINES

DIVERSE DESIGN OF THE FRONT PANEL

The main rack and dryer models are available in four different visual options which differ in the design of the front column. The Standard line is featured by a classic anthracite frontside, whilst the MiniPanel line by a modern white panel with a contrasting solid handle. The Panel line is distinguished by a wide, elegant board with an oval stainless-steel handle attached to it; the UniQ line offers unlimited possibilities for the selection of materials, which includes a delicate casing of a wide front column with a comfortable inner handle. The choice of different visual lines enables QBL products to be properly matched to the interior design and character of the facility in which they are used.

Adjustable structural systems

Optimal use of available space

QBL products are designed to allow, as much as possible, for the individual components to be adapter to the types and sizes of equipment they store. Thanks to smart functional solutions, adapting the location of the forks, adjusting the mounting height of the levels, shelves or aluminium crossbars is very simple and intuitive. Adjustment systems mean optimal use of the available space – which translates directly into increased storage capacity.

WALL MOUNTING

ARRANGING WALL SPACE FOR STORAGE OR DRYING PURPOSES

Lighter storage systems such as levels for skis, poles or snowboards and one-sided dryers with smaller capacities are designed to be hung on the wall. Thanks to this solution, virtually any available space in the rental shop, storage room or apartment can be used more effectively. One-sided steel structures have special fastenings, allowing simple and safe hanging of products on pegs anchored into the wall – at any height and adjusted to the size of the stored equipment.

GRIP OF SKIS_ THE CLIQ HOLDER

INNOVATIVE & SUPEREFFICIENT SKI HOLDING SYSTEM

The CliQ holder has been designed to maximise the storage functionality of the skis. Its uniqueness lies in its effective combination of several key features: secure hold on equipment, exceptional ease of use, the possibility of storing different types, lengths and widths of skis and impressive presentation. The innovative design and the patented operating mechanism of the holder allow to insert your skis intuitively and quickly – with just one hand. Slight pressing of the rubbercoated spring plate closes the arms, which stiffen the skis in the holder extremely firmly. The skis are stored at an angle of 22°, which gives them a truly attractive display. There are two models of the CliQ Holder for differents ski categories_ CliQ and CliQ XL.

GRIP OF SKIS_ 3-POINT SYSTEM

VERSATILE & EXTREMELY SECURE HOLDING SYSTEM

The holding technique is based on the universal three-point system of contact between the surface of the rack and the surface of the skis. The key to the maximum functionality of the system is the optimal proportions of individual structural elements and the angles of their location in relation to each other. Not only do they provide an exceptionally strong hold on the equipment, allowing to use all types and widths of skis (including cross-country), but they are also safe to store without causing unwanted changes to the construction of skis over long periods of use. Designed specifically for the three-point holding system, the aluminium upper crossbars (with their special rubber seal) securely hold skis in the rack – even when they are put away carelessly in a hurry.

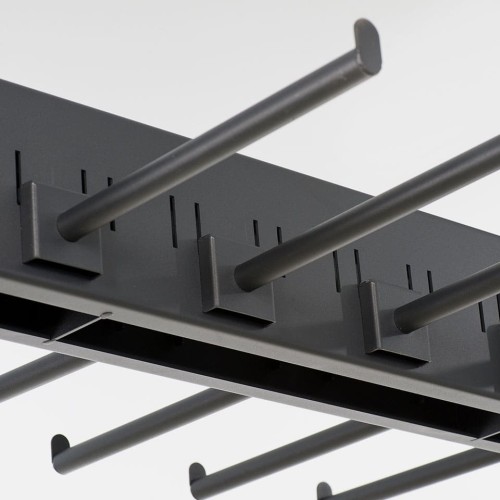

GRIP OF SKIS_ NEW FORK SYSTEM

BY FAR THE MOST SPACEEFFICIENT HOLDING SYSTEM

The fork-based system is the most capacious way to store skis. The forks are made of 3mm-thick steel and four steel tubes to hang the skis on. The surface of the forks is covered with a rubber coat, which has anti-slip properties and effectively protects them from scratches. The forks are fixed at any distance on the steel levels – allowing maximum use of the available space on the rack. The structure has been designed in such a way that, thanks to the gentle slope of the steel tubes, the risk of equipment falling out during dynamic movement or collision of the racks is reduced. Each fork can safely store two to three pairs of senior skis.

GRIP OF SNB_ HORIZONTAL SYSTEM

TRADITIONAL & UNIVERSAL WAY OF HOLDING SNOWBOARDS

The traditional horizontal storage of snowboards is simple and universal in use and allows the storage of boards of various sizes – with both classic and rental bindings. The structure consists of two columns with holes along their entire height, used for attaching pairs of hooks on which snowboards are placed. The spacing between the hooks, thanks to the densely perforated columns, can be varied to optimise the use of available space. The upper surface of the hooks is covered with a rubber coat which has anti-slip properties and effectively protects them from scratches. One level of hooks can store one board with classic binding or two boards with rental bindings.

GRIP OF SNB_ 3-POINT SYSTEM

VERTICAL STORAGE WITH EXCEPTIONAL CAPACITY

The technique of holding snowboards in a vertical position is based on a three-point contact system of the rack with the edge of the snowboard, ensuring not only a firm hold of the equipment, but also the safety of its storage. The system consists of upper and lower aluminium crossbars with blue plastic elements attached to them as partitions between boards, and a galvanised steel hood. The hood has a channel that drains water away from the rack. The storage of snowboards in a vertical position brings extraordinary capacity and functionality. The mounting positions of the crossbars which hold the boards can be adjusted to suit the size of the equipment stored.

GRIP OF SKIS_ MINIDEPOT BOX

Lockable box to secure a pair of skis and of poles

BIKE-HOLDING SYSTEM

A DEDICATED SOLUTION FOR BIKE STORAGE FACILITIES

The system of holding bikes in a vertical position has a complex steel structure that allows for the best spacesaving storage of bicycles. The lower structural elements, mounted on the rack frame, stabilise the rear wheel and prevent it from tilting horizontally. The upper handles, which are mounted on the crossbar, keep the wheels in a twisted position – for better stability, safety and for ergonomic storage. The exceptional capacity of the system is ensured by the fact that bicycles mounted on both sides of the rack can pass each other and by the diagonal position of the handle and the front wheel. The height of the crossbar and the positions of the upper and lower handles are adjusted to the dimensions of the stored bicycles.

POLE FORKS

CAPACITY & CONVENIENCE OF STORAGE

The storage of ski poles is based on forks made of 2 mm-thick galvanised sheet steel. Their design includes two long contoured arms between which the poles are inserted. The forks are mounted in steel levels with numerous holes spaced at two or four heights, allowing the forks location to be optimally matched to the length of the poles. Each standard-length fork holds up to four pairs of poles and is finished with a pair of plastic elements to keep the poles from falling out. The available colours of the plastic tips correspond to the length markings of the rental poles, helping you to store them in the right order.

ERGONOMIC SHELVES

MORE STORAGE POSSIBILITIES

Shelves are the main component of some products, but they are also a very useful optional accessory for virtually every model of the rack. Thanks to their design and dimensions, they are perfect for storing helmets, boots and many other accessories. Additionally, the solution of mounting them at a slight angle reduces the risk of equipment falling out when the racks are dynamically moved or collided. With the adjustment systems in the racking columns, the mounting heights of the shelves and the spacing between them can be adapted to the size of the equipment stored. The edges of the shelves have been rounded off to avoid stripping the equipment and to prevent hand injuries when taking boots from the rack. The shelves are made of highquality 1.5mm galvanised steel and are powder-coated.

Single Forks

FOR A VARIETY OF STORAGE NEEDS

The single fork is designed as an alternative universal solution for various storage needs, including snowshoes, snowboard bindings and ski poles. The simplicity of design gives the fork exceptional utility. The 22mm diameter of the steel tube that the equipment hung on has a widened end to prevent it from falling out. The fixing of the single fork in the holes corresponds to the fixing of the pole fork so that both elements can be used interchangeably on one construction level. Thanks to the compact form of the steel level, it may be attached to standard shelving models as additional storage solution.

POST WITH HOOKS

OPTIONAL STORAGE OF POLES

A post with profiled steel hooks is an optional racking component for hanging ski poles or other accessories. The post is mounted at any height of the columns, at the top of ski racks – most often in situations where skis should be stored together with their poles (e.g. in small ski depots or for private use).

STEEL BOX

SPACIOUS EXTRA STORAGE CAPACITY FOR BINDINGS OR OTHER ACCESSORIES

The capacious steel basket is made of 1mm-thick perforated sheet metal covered with powder coating. Thanks to additional zinc protection, it is resistant to moisture. The basket is located on a frame at the bottom of the rack and is intended for storing rental snowboard bindings, helmets and other types of gear. The interior structure is open, or – on request – divided, thus allowing different categories or sizes of equipment to be stored in separate compartments.

STEEL LEVEL FOR HANGERS

Simple design for maximum storage capacity

RUNNING SYSTEM

Space-saving, mobile and convenient

The running system of QBL products includes a rail set or a set of swivel casters. The rail set consists of stainless steel rails 2 or 3mm thick (depending on the length of the racks), connectors, rail endings, and 12 standard bearings attached to each frame of rack or dryer. The design of the rails and the number of bearings used guarantee smooth and safe movement of the products – even when fully loaded. The set of swivel casters includes four durable casters (with a diameter of 75, 80 or 125mm) which are selected according to the needs and the maximum possible load on the structure.

FRAME

RIGID STRUCTURE, SAFETY OF USE

All racks and dryers in the rail system are equipped with a structural frame made of 3mm-thick steel, which is their load-bearing base and ensures the rigidity and stability of the entire system. The frame also acts as a running structure, ensuring safe and even guidance of products on the rails. The frame is double protected against corrosion – it is made of galvanised steel and covered with a layer of powder coating.

WATER HOOD

WATER DRAINAGE & SUPPORT POINT FOR SKIS AND SNOWBOARDS

The water hood is made of galvanised steel or (optionally) stainless steel with a thickness of 1.5mm, thus maintaining its anti-corrosion properties. It is located on a frame designed with a slight angle of inclination so that dripping water from skis or snowboards does not accumulate but flows away through the hood channel outside the rack and its rail system. The thoughtful design of the water hood not only drains water, but is also a component of the three-point holding system for skis and snowboards.

WATER TUB

WATER COLLECTION – THE COMFORT OF A DRY FLOOR

Racks and dryers with an open interior of the frame can be optionally equipped with a steel tub with a rubber mat, which serves for collecting water and dirt dripping from stored skis, snowboards or dried boots. The tub is made of galvanised steel, thus maintaining its resistance to corrosion. Adjusting the structure to the frames of the racks and dryers allows for easy removal and emptying. The use of the tub reduces moisture and dirt on the floor and in the area of the rail system.

Safe transport of ski equipment

Non-slip rubber mat and durable rubber seals for secure support

RUNNING SYSTEM

Four swivel casters with brakes for convenient and safe handling

OPENING NOZZLE SYSTEM

INCREASED EFFICIENCY & ENERGY-SAVING

The aluminium or steel arms are finished with a specially designed nozzles comprised of a spring and a plastic ending – different for each type of dried equipment – footwear, helmets and gloves. The nozzles activate when the equipment is placed on the arm, which – by pressing the spring – opens the air supply from the dryer. When the equipment is removed, the nozzle system automatically closes, preventing heated air from escaping ineffectively to the outside. Additional openings at the base of the arms allow air to be forced into the upper parts of the boots. The open nozzle system contributes to a significant increase in drying performance and energy efficiency.

SHELVES WITH HEATING MODULES

HIGH PRESSURE AIR FLOW COMING DOWN FROM EACH SHELF

The Wind model of dryers use a heating system based on separate modules – each consisting of a fan and a heater. The drying modules are placed in 9 of the 11 shelves (excluding the lowest mounted shelf on each side). The shape of their structure and the high efficiency of the fans used ensure a sufficiently high pressure of the air flow. The bottom surface of each shelf has numerous openings through which heated air is blown into the boots placed below. The shelves are made of galvanised steel and their fixing height can be adjusted to the size of the stored boots. Units with shelves and built-in heating modules combine the functions of dryers and storage racks.

TWO ENERGY-SAVING MODES

IDEAL FOR APARTMENTS – QUIET NIGHT MODE & EFFICIENT DAY MODE

Supreme drying units are based on a heating system that consists of an energy-efficient heating cable and a small fan (Supreme Hybrid version). Two stainless, backlit buttons located in the housing correspond to the two alternative operating modes of the system. The first is an 8-hour silent night mode, in which the heating cable heats the steel tubing on which the boots are worn; the second is a 4-hour day mode, in which the heating cable and fan run simultaneously (short drying before the next ski adventure). At the end of the programmed time, the dryer's heating functions automatically stop.

TOUCHSCREEN

COMMUNICATION BETWEEN THE USER & THE DEVICE

Double-sided boot dryers – Optiflow, Force and Wind models – are operated through 5"colourful touchscreen built into the side wall of the main control cabinet. A large, sensitive display and an intuitive application make navigating the menu and managing all available functions of the device very simple and friendly. In addition to a range of functions of the dryer, the screen allows you to select, among other things, one of the six available language versions. There is also an automatic ‘lock screen’ function to prevent unauthorised control of the device. The communication between the user and the Panel models is ensured by a touchscreen 3.5".

ELECTRONIC CONTROL

OPTIMISATION & OPERATIONAL EFFICIENCY

The electronic dryer control system allows efficient and customised operation of the dryers. Its functionality is demonstrated by the availability of multiple useful settings and intuitive control of individual functions of the device (e.g. heating temperature, disinfection or time controller). The double-sided dryer models are divided into three independent segments. The operation of each of them can be adjusted individually by stopping their work or by setting one of three modes: fan, fan with heaters and work according to pre-set time intervals. The timer function allows individual operating modes to be set for each hour of each day of the week separately. The electronic control system helps to optimise the operation of the appliance while increasing drying efficiency and energy savings.

DRYING EFFICIENCY

CAREFULLY DESIGNED SYSTEMS & SELECTED COMPONENTS

The drying systems consist of highquality industrial components – durable and adapted to continuous, uninterrupted operation. Each of the components used – and which affect the efficiency of the dryer (i.e. primarily heaters and fans) – were subjected to long-term tests, also in conditions of increased humidity and a wide range of ambient temperatures. Careful selection of individual elements with specific performance parameters, as well as optimal selection of their configuration, number, or appropriate location in the construction of the equipment – ensure the dryers’ (especially double-sided models) exceptional durability and drying efficiency. It is possible to use components suitable for electric networks with different parameters (including 110-120V AC).

DISINFECTION SYSTEM

TWO PROVEN METHODS FOR DISINFECTING EQUIPMENT

Larger dryer models can be equipped with an internal boot disinfection system or a high-quality UV lamp. The built-in disinfection system consists of a tank, a dosing pump, supply pipes and nozzles spraying liquid particles inside the device, which are forced into the boots together with air. Operation of the disinfection system is only possible in fan mode and is controlled via the touchscreen and menu control system. The long-life lamp is mounted inside the structure of dryers, continuously emitting Type C ultraviolet waves (UV-C) with germicidal properties.

PROTECTION SYSTEM

SAFETY OF USE

Protection of electrical systems against overheating and damage to components in each dryer for boots, helmets or gloves is ensured by a bi-metal thermal protection system. The Force, Optiflow, Wind and Panel models are additionally equipped with independent systems of programmable thermal protection – thanks to which, the heating systems are automatically cooled down in the event of a failure or a sudden, undesirable shutdown of the device. All models of QBL dryers and all carefully selected components have CE declarations of conformity.

SMART STORAGE

PRECISELY DESIGNED STORAGE SOLUTIONS

The interior of each ski locker has spaces dedicated to different categories of ski equipment – ensuring safety, comfort and proper storage organisation. One part of the back wall is covered by a ventilation duct with steel tubes for ski boots. Depending on the configuration of the lockers chosen by the customer, the duct may also contain modules adapted for drying helmets and/or gloves. The pairs of skis or snowboards rest against the free space of the back wall just in front of the poles which hang behind. In the basic version, helmets and gloves are stored on hooks located directly above the footwear. Goggles, beanies and other smaller items of clothing can be hung up or placed in the optional practical net mounted on the inside of the door.

HEATING SYSTEM

EFFICIENT DRYING OF STORED EQUIPMENT

In the upper part of the ventilation duct of each ski locker, there is a fan which, together with additional heating cable system, forms an integrated module for drying of ski equipment – boots and, optionally, helmets and gloves. The air stream generated by the fan flows through the duct and is forced through the steel tubes directly into the equipment stored in the locker. The power cord for each locker is plugged into a special main power cord that runs under the top covers of the lockers directly to the room power outlet. The separate connection of power cables for ventilation and heating, enables independent control of the fans and heating cables and programming of their operation at set time intervals.

DOOR MODELS

WIDE RANGE OF ATTRACTIVE FORMS & MATERIALS

The door is the most visible element of the lockers, that is used intensively and directly, resultantly influencing the assessment of the quality of the lockers by their users. The basic version consists of a rigid frame and a single galvanised steel layer. The double model has two galvanised layers of steel and a soundproofing space between them, giving the door structure extra thickness, rigidity and weight. Board doors are made entirely of high-quality melamine panels with a decorative layer with deep structure, low pattern repeatability and exceptional durability and abrasion resistance. The Sequence model has double reinforced door construction, which includes upper and lower parts on the front side which are selected according to individual preferences – from multi-coloured steel plates, melamine boards, natural wood or rubber mats with anti-slip properties, which allow the skis to rest against the locker doors.

LOCKING SYSTEMS

FROM TRADITIONAL TO INNOVATIVE SOLUTIONS

Locking systems and access to ski depot rooms include many different solutions – from traditional key locks, through offline systems such as battery-operated locks, to complex online solutions using RFID technology, which enables remote management of lockers, including their reservation. The structures of depot lockers, especially doors, are – each time – adapted to the model of locks chosen by the customer and the readers used by the manufacturer in the case of electronic online systems. Experience and many years of cooperation with renowned international lock manufacturers guarantee a smooth and effective implementation process, including configuration or possible integration with independent hotel software and correct operation of the solutions used.

TOP COVERS

ELEGANT COVERS FOR HEATING & ACCESS SYSTEMS

Made of steel, the upper covers of depot lockers have two important functions – they cover and encase the upper surface of lockers and make their form more attractive. Each locker has power cables for the heating system and wiring for the electronic locking system – supplying and connecting the locks into one network. Mounted with steel hooks, the covers effectively protect electronics against unauthorised access and damage. The slanting front surface and the height of the covers give the lockers a modern character and complete their shape.

SIDE COVERS

CONSISTENT FINISHES TO ROWS OF LOCKERS

Side covers are used to cover the outer side walls of ski lockers in situations where the row is not attached to a wall but ends in a visible, open area of the ski depot. The structure of side covers is made of steel – usually in a colour which corresponds to the colour of the locker plating – or of furniture boards. Thanks to the precise adjustment of the cover to the locker structure and its modern form, the endings of the rows of lockers – both single and double – look consistent and elegant. The side covers often contain central readers used to open the electronic locks assigned to them using RFID technology.

FLOOR PLATES

STABLE STORAGE & WATER DRAINAGE

The bottom of the depot locker, on which skis or snowboards are placed, is one of the two floor plates fitted to the locker. These are: a tub made of galvanised perforated steel and a stainless steel tub – in a closed version or with several drainage holes. When a perforated tub is used, water dripping from skis or boots gets through the grating directly under the locker. A full stainless-steel tub retains water, while drainage holes allow water to be drained into a tank placed under the locker or for a drainage pipe system to be installed. The floor plates can be additionally equipped with anti-slip rubber mats.

RUBBER MATS

FUNCTIONAL BENEFITS & ENHANCED USER SAFETY

Rubber mats are made from a specialised microporous foam and provide an advanced covering for the top fillings of depot locker doors. Due to their non-slip properties, they allow to comfortably rest skis on the front of the doors, thus increasing the safety of using the ski depots. In addition to their superior utility function and visual benefits, the mats are also characterized by their ability to withstand flames, weather conditions and extreme temperatures.

ACCESSORIES

LOTS OF PRACTICAL EXTRAS

The concept of an innovative ski depot assumes, apart from safety, drying efficiency or well-thoughtout organisation of storage, the use of additional functionalities, which will all be noticed and appreciated by users. That's why our depot lockers can include extras like LED backlighting, power and USB outlets, hooks, practical storage nets for personal belongings or mirrors so that you can quickly get ready for the upcoming Après-ski.

BLINDS

VISUAL & FUNCTIONAL COMPLEMENT

Depot Lockers form a unified and coherent body. Its visual complement are blinds, which close the space under the locker from the front – within the four steel legs. On the practical side, blinds block access to the space underneath lockers and limit the accumulation of dirt. Blinds are available in two versions – as a stainless-steel plate and a galvanised steel plate. Both types are easily attached and detached from the locker thanks to a system of small magnets.

TECHNOLOGY

42 ITEMS

General

PERSONALISATION

SELECT FROM VARIOUS MATERIALS & COLOURS

General

DOUBLE PROTECTION

DURABILITY & PROTECTION AGAINST CORROSION

General

FOUR VISUAL LINES

DIVERSE DESIGN OF THE FRONT PANEL

General

Adjustable structural systems

Optimal use of available space

General

WALL MOUNTING

ARRANGING WALL SPACE FOR STORAGE OR DRYING PURPOSES

Storage

GRIP OF SKIS_ THE CLIQ HOLDER

INNOVATIVE & SUPEREFFICIENT SKI HOLDING SYSTEM

Storage

GRIP OF SKIS_ 3-POINT SYSTEM

VERSATILE & EXTREMELY SECURE HOLDING SYSTEM

Storage

GRIP OF SKIS_ NEW FORK SYSTEM

BY FAR THE MOST SPACEEFFICIENT HOLDING SYSTEM

Storage

GRIP OF SNB_ HORIZONTAL SYSTEM

TRADITIONAL & UNIVERSAL WAY OF HOLDING SNOWBOARDS

Storage

GRIP OF SNB_ 3-POINT SYSTEM

VERTICAL STORAGE WITH EXCEPTIONAL CAPACITY

Storage

GRIP OF SKIS_ MINIDEPOT BOX

Lockable box to secure a pair of skis and of poles

Storage

BIKE-HOLDING SYSTEM

A DEDICATED SOLUTION FOR BIKE STORAGE FACILITIES

Storage

POLE FORKS

CAPACITY & CONVENIENCE OF STORAGE

Storage

ERGONOMIC SHELVES

MORE STORAGE POSSIBILITIES

Storage

Single Forks

FOR A VARIETY OF STORAGE NEEDS

Storage

POST WITH HOOKS

OPTIONAL STORAGE OF POLES

Storage

STEEL BOX

SPACIOUS EXTRA STORAGE CAPACITY FOR BINDINGS OR OTHER ACCESSORIES

Storage

STEEL LEVEL FOR HANGERS

Simple design for maximum storage capacity

Storage

RUNNING SYSTEM

Space-saving, mobile and convenient

Storage

FRAME

RIGID STRUCTURE, SAFETY OF USE

Storage

WATER HOOD

WATER DRAINAGE & SUPPORT POINT FOR SKIS AND SNOWBOARDS

Storage

WATER TUB

WATER COLLECTION – THE COMFORT OF A DRY FLOOR

Storage

Safe transport of ski equipment

Non-slip rubber mat and durable rubber seals for secure support

Storage

RUNNING SYSTEM

Four swivel casters with brakes for convenient and safe handling

Dryers

OPENING NOZZLE SYSTEM

INCREASED EFFICIENCY & ENERGY-SAVING

Dryers

SHELVES WITH HEATING MODULES

HIGH PRESSURE AIR FLOW COMING DOWN FROM EACH SHELF

Dryers

TWO ENERGY-SAVING MODES

IDEAL FOR APARTMENTS – QUIET NIGHT MODE & EFFICIENT DAY MODE

Dryers

TOUCHSCREEN

COMMUNICATION BETWEEN THE USER & THE DEVICE

Dryers

ELECTRONIC CONTROL

OPTIMISATION & OPERATIONAL EFFICIENCY

Dryers

DRYING EFFICIENCY

CAREFULLY DESIGNED SYSTEMS & SELECTED COMPONENTS

Dryers

DISINFECTION SYSTEM

TWO PROVEN METHODS FOR DISINFECTING EQUIPMENT

Dryers

PROTECTION SYSTEM

SAFETY OF USE

Lockers

SMART STORAGE

PRECISELY DESIGNED STORAGE SOLUTIONS

Lockers

HEATING SYSTEM

EFFICIENT DRYING OF STORED EQUIPMENT

Lockers

DOOR MODELS

WIDE RANGE OF ATTRACTIVE FORMS & MATERIALS

Lockers

LOCKING SYSTEMS

FROM TRADITIONAL TO INNOVATIVE SOLUTIONS

Lockers

TOP COVERS

ELEGANT COVERS FOR HEATING & ACCESS SYSTEMS

Lockers

SIDE COVERS

CONSISTENT FINISHES TO ROWS OF LOCKERS

Lockers

FLOOR PLATES

STABLE STORAGE & WATER DRAINAGE

Lockers

RUBBER MATS

FUNCTIONAL BENEFITS & ENHANCED USER SAFETY

Lockers

ACCESSORIES

LOTS OF PRACTICAL EXTRAS

Lockers

BLINDS

VISUAL & FUNCTIONAL COMPLEMENT