Boot Dryer Football

Boots 100%

PRODUCT LINE_ Standard

-

PRODUCT DESCRIPTION

-

Made in EU

Made in EU

24 Months Guarantee

24 Months Guarantee

SPECIFICATION_

| LENGTH MM | CAPACITY pairs of boots | POWER CONSUMPTION*W |

| 1000 | 36 | 260/4000 |

| 1250 | 48 | 260/4000 |

| 1500 | 60 | 260/5680 |

| 1800 | 72 | 260/5680 |

| HEIGHT 2250 mm | WIDTH 800 mm | VOLT.* 230/3x400 V |

*without heating / with heating

DOUBLE PROTECTION

DURABILITY & PROTECTION AGAINST CORROSION

The key elements of racks and dryers exposed to corrosion (such as frames, levels, angles or shelves, as well as depot lockers structures) are made of high-quality galvanised steel. During the final stage of production, all elements are subject to automated powder coating. Galvanised steel and a thick layer of coating provide double protection for the products against moisture. In addition, the rack structures have been designed to prevent water accumulation inside the

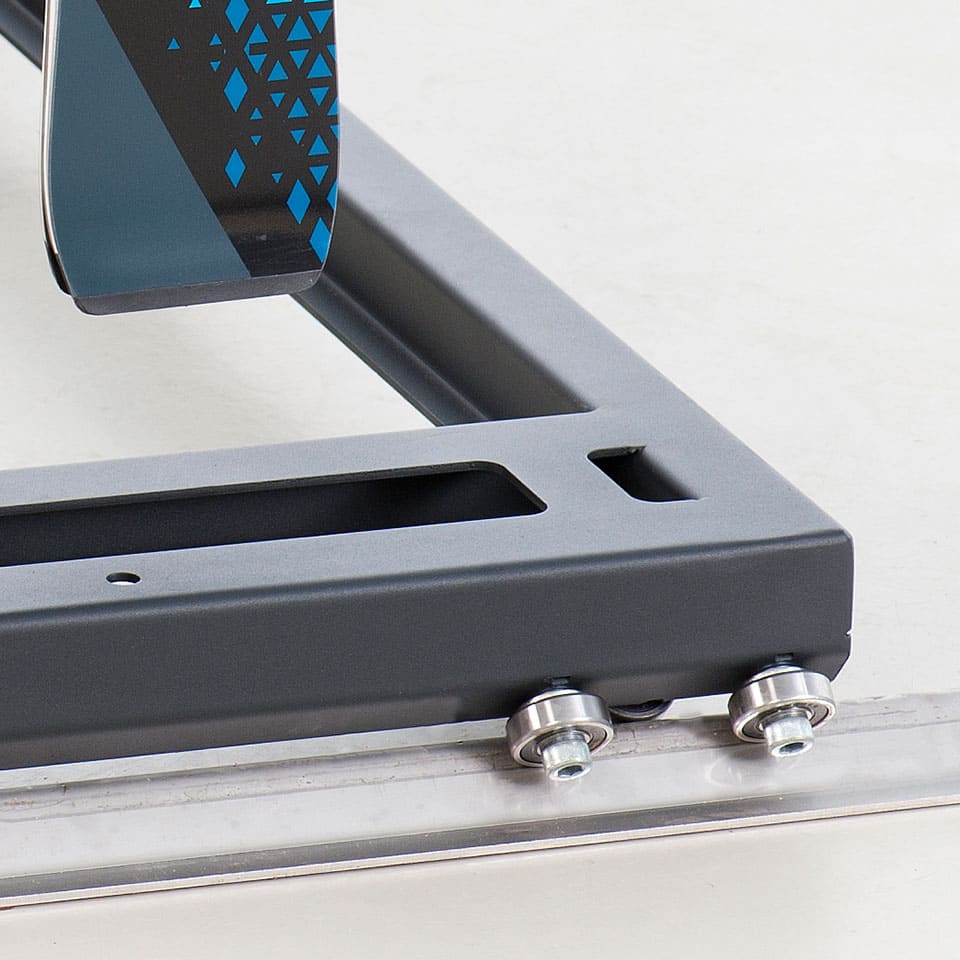

RUNNING SYSTEM

Space-saving, mobile and convenient

The running system of QBL products includes a rail set or a set of swivel casters. The rail set consists of stainless steel rails 2 or 3mm thick (depending on the length of the racks), connectors, rail endings, and 12 standard bearings attached to each frame of rack or dryer. The design of the rails and the number of bearings used guarantee smooth and safe movement of the products – even when fully loaded. The set of swivel casters includes four durable casters (with a diameter of 75, 80 or 125mm) which are selected according to the needs and the maximum possible load on the structure.

FRAME

RIGID STRUCTURE, SAFETY OF USE

All racks and dryers in the rail system are equipped with a structural frame made of 3mm-thick steel, which is their load-bearing base and ensures the rigidity and stability of the entire system. The frame also acts as a running structure, ensuring safe and even guidance of products on the rails. The frame is double protected against corrosion – it is made of galvanised steel and covered with a layer of powder coating.

WATER TUB

WATER COLLECTION – THE COMFORT OF A DRY FLOOR

Racks and dryers with an open interior of the frame can be optionally equipped with a steel tub with a rubber mat, which serves for collecting water and dirt dripping from stored skis, snowboards or dried boots. The tub is made of galvanised steel, thus maintaining its resistance to corrosion. Adjusting the structure to the frames of the racks and dryers allows for easy removal and emptying. The use of the tub reduces moisture and dirt on the floor and in the area of the rail system.

TOUCHSCREEN

COMMUNICATION BETWEEN THE USER & THE DEVICE

Double-sided boot dryers – Optiflow, Force and Wind models – are operated through 5"colourful touchscreen built into the side wall of the main control cabinet. A large, sensitive display and an intuitive application make navigating the menu and managing all available functions of the device very simple and friendly. In addition to a range of functions of the dryer, the screen allows you to select, among other things, one of the six available language versions. There is also an automatic ‘lock screen’ function to prevent unauthorised control of the device. The communication between the user and the Panel models is ensured by a touchscreen 3.5".

ELECTRONIC CONTROL

OPTIMISATION & OPERATIONAL EFFICIENCY

The electronic dryer control system allows efficient and customised operation of the dryers. Its functionality is demonstrated by the availability of multiple useful settings and intuitive control of individual functions of the device (e.g. heating temperature, disinfection or time controller). The double-sided dryer models are divided into three independent segments. The operation of each of them can be adjusted individually by stopping their work or by setting one of three modes: fan, fan with heaters and work according to pre-set time intervals. The timer function allows individual operating modes to be set for each hour of each day of the week separately. The electronic control system helps to optimise the operation of the appliance while increasing drying efficiency and energy savings.

DRYING EFFICIENCY

CAREFULLY DESIGNED SYSTEMS & SELECTED COMPONENTS

The drying systems consist of highquality industrial components – durable and adapted to continuous, uninterrupted operation. Each of the components used – and which affect the efficiency of the dryer (i.e. primarily heaters and fans) – were subjected to long-term tests, also in conditions of increased humidity and a wide range of ambient temperatures. Careful selection of individual elements with specific performance parameters, as well as optimal selection of their configuration, number, or appropriate location in the construction of the equipment – ensure the dryers’ (especially double-sided models) exceptional durability and drying efficiency. It is possible to use components suitable for electric networks with different parameters (including 110-120V AC).

DISINFECTION SYSTEM

TWO PROVEN METHODS FOR DISINFECTING EQUIPMENT

Larger dryer models can be equipped with an internal boot disinfection system or a high-quality UV lamp. The built-in disinfection system consists of a tank, a dosing pump, supply pipes and nozzles spraying liquid particles inside the device, which are forced into the boots together with air. Operation of the disinfection system is only possible in fan mode and is controlled via the touchscreen and menu control system. The long-life lamp is mounted inside the structure of dryers, continuously emitting Type C ultraviolet waves (UV-C) with germicidal properties.

PROTECTION SYSTEM

SAFETY OF USE

Protection of electrical systems against overheating and damage to components in each dryer for boots, helmets or gloves is ensured by a bi-metal thermal protection system. The Force, Optiflow, Wind and Panel models are additionally equipped with independent systems of programmable thermal protection – thanks to which, the heating systems are automatically cooled down in the event of a failure or a sudden, undesirable shutdown of the device. All models of QBL dryers and all carefully selected components have CE declarations of conformity.

TECHNOLOGIES_

DOUBLE PROTECTION

DURABILITY & PROTECTION AGAINST CORROSION

RUNNING SYSTEM

Space-saving, mobile and convenient

FRAME

RIGID STRUCTURE, SAFETY OF USE

WATER TUB

WATER COLLECTION – THE COMFORT OF A DRY FLOOR

TOUCHSCREEN

COMMUNICATION BETWEEN THE USER & THE DEVICE

ELECTRONIC CONTROL

OPTIMISATION & OPERATIONAL EFFICIENCY

DRYING EFFICIENCY

CAREFULLY DESIGNED SYSTEMS & SELECTED COMPONENTS

DISINFECTION SYSTEM

TWO PROVEN METHODS FOR DISINFECTING EQUIPMENT

PROTECTION SYSTEM

SAFETY OF USE