-

PRODUCT DESCRIPTION

-

Made in EU

Made in EU

24 Months Guarantee

24 Months Guarantee

PRODUCT DESCRIPTION_

Boot Dryer Force is one of the most efficient devices of this type available on the market. The electrical system is divided into three segments, and it is made of high-quality components designed for continuous operation. All functions of the dryer are controlled using a touchscreen. Using a few buttons you can set the operating mode of each segment, its air temperature and drying times. The arms, on which boots are placed, are replaceable and equipped with nozzles with a spring which opens air supply only when a boot is placed on the arm. The function of controlling the segments, adjusting working hours and the open-close nozzle system contribute substantially to the high effectiveness of drying and energy efficiency of the device. The Boot Dryer can be equipped with an integrated disinfection system or a germicidal lamp.

SPECIFICATION_

| LENGTH MM | CAPACITY PAIRS OF BOOTS | POWER CONSUMPTION*W |

| 1500 | 48 | 260/5680 |

| 1800 | 60 | 260/5680 |

| 2000 | 72 | 510/7730 |

| 2400 | 84 | 510/7730 |

| 3000 | 108 | 510/7730 |

| 4000 | 144 | 2X510/7730 |

| HEIGHT 2250 mm | WIDTH 800 mm | VOLT.* 230/3X400 V |

* Without heating / with heating

DOUBLE PROTECTION

DURABILITY & PROTECTION AGAINST CORROSION

FOUR VISUAL LINES

DIVERSE DESIGN OF THE FRONT PANEL

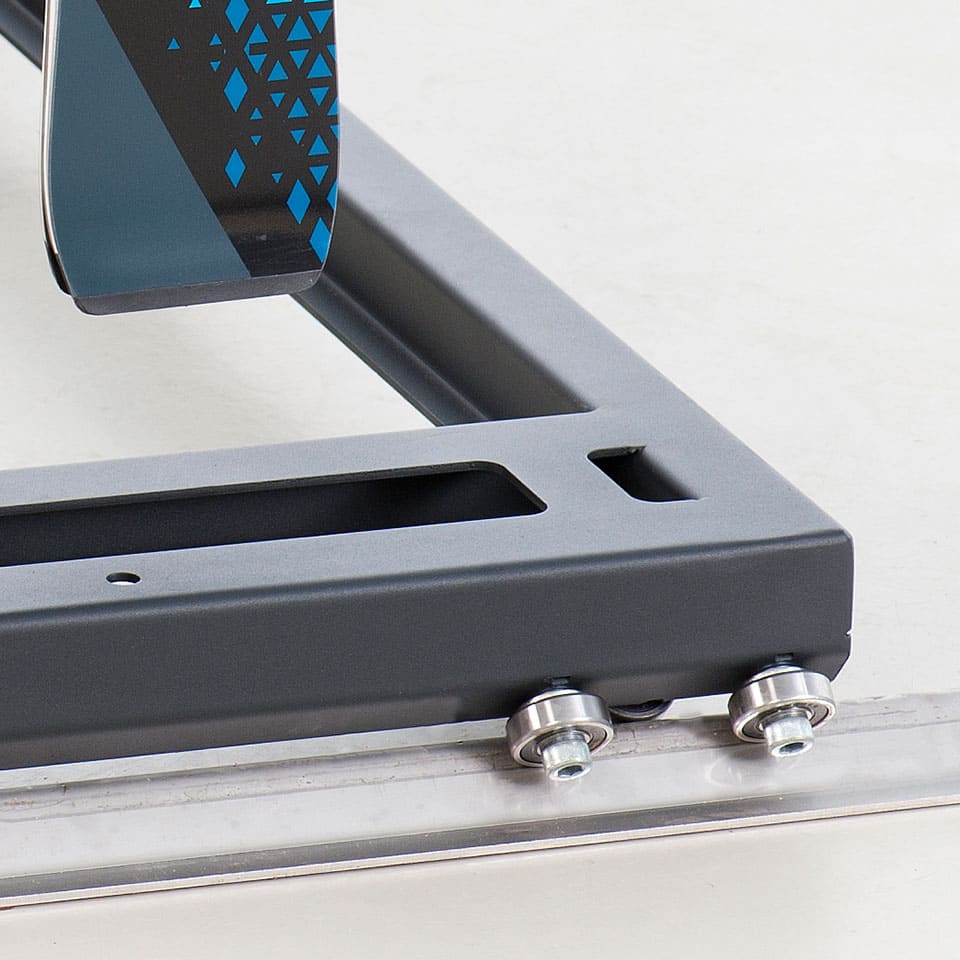

RUNNING SYSTEM

Space-saving, mobile and convenient

WATER TUB

WATER COLLECTION – THE COMFORT OF A DRY FLOOR

OPENING NOZZLE SYSTEM

INCREASED EFFICIENCY & ENERGY-SAVING

TOUCHSCREEN

COMMUNICATION BETWEEN THE USER & THE DEVICE

ELECTRONIC CONTROL

OPTIMISATION & OPERATIONAL EFFICIENCY

DRYING EFFICIENCY

CAREFULLY DESIGNED SYSTEMS & SELECTED COMPONENTS

DISINFECTION SYSTEM

TWO PROVEN METHODS FOR DISINFECTING EQUIPMENT

PROTECTION SYSTEM

SAFETY OF USE

TECHNOLOGIES_

DOUBLE PROTECTION

DURABILITY & PROTECTION AGAINST CORROSION

FOUR VISUAL LINES

DIVERSE DESIGN OF THE FRONT PANEL

RUNNING SYSTEM

Space-saving, mobile and convenient

WATER TUB

WATER COLLECTION – THE COMFORT OF A DRY FLOOR

OPENING NOZZLE SYSTEM

INCREASED EFFICIENCY & ENERGY-SAVING

TOUCHSCREEN

COMMUNICATION BETWEEN THE USER & THE DEVICE

ELECTRONIC CONTROL

OPTIMISATION & OPERATIONAL EFFICIENCY

DRYING EFFICIENCY

CAREFULLY DESIGNED SYSTEMS & SELECTED COMPONENTS

DISINFECTION SYSTEM

TWO PROVEN METHODS FOR DISINFECTING EQUIPMENT

PROTECTION SYSTEM

SAFETY OF USE